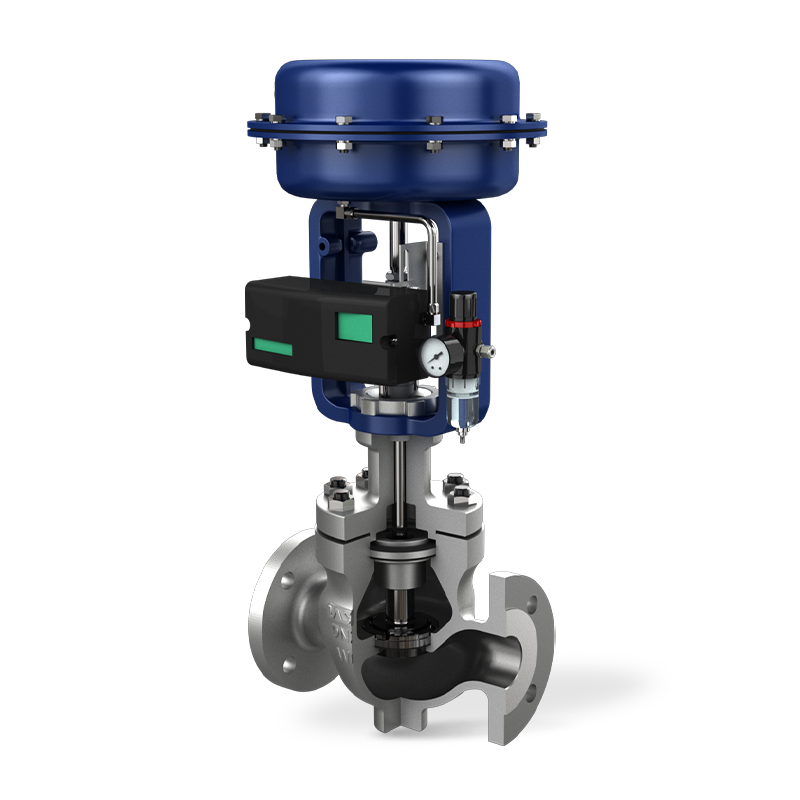

Zhejiang Lasen Intelligent Equipment Co., Ltd. ( Used to be known as Hangzhou Lasen Valve Co., Ltd. ), located in Hangzhou Changkou industrial zone, which is on the Bank of Fuchun River. Founded in 2004 with a registered capital of 100 million yuan, the company is a science and technology enterprise integrating R & D, production, sales, and maintenance of control valves. Zhejiang Lasen Intelligent Equipment Co., Ltd. is Carbon Steel Eccentric Butterfly Valve Manufacturer and Carbon Steel Eccentric Butterfly Valve Supplier.

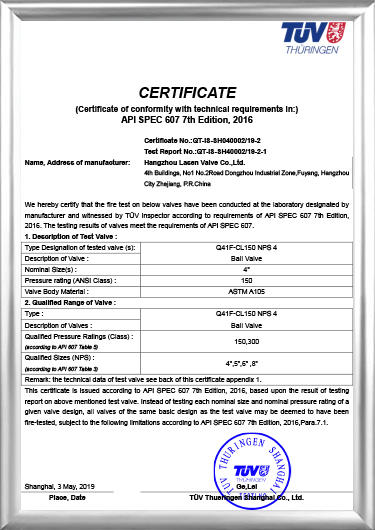

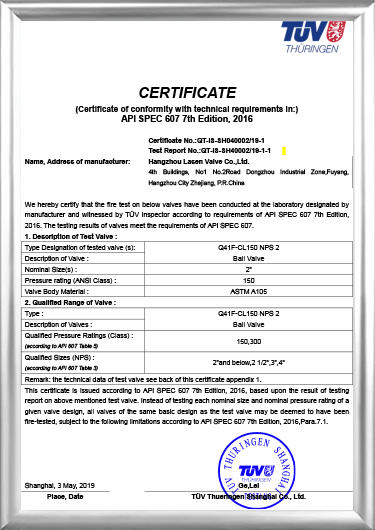

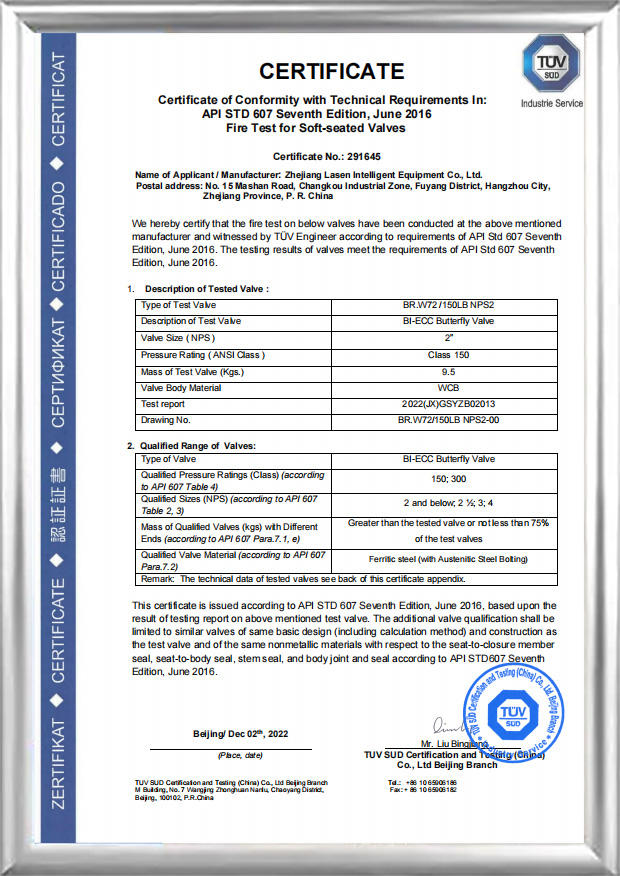

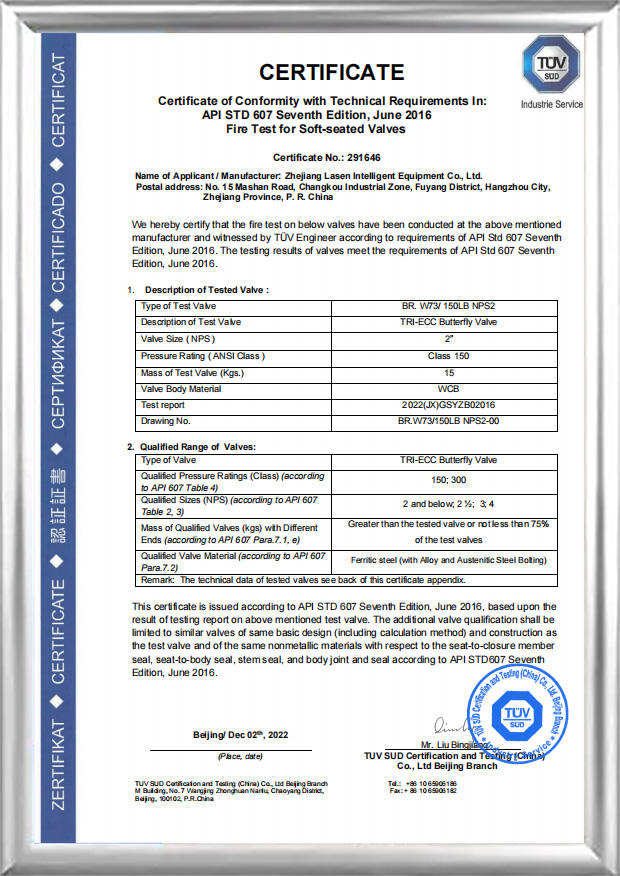

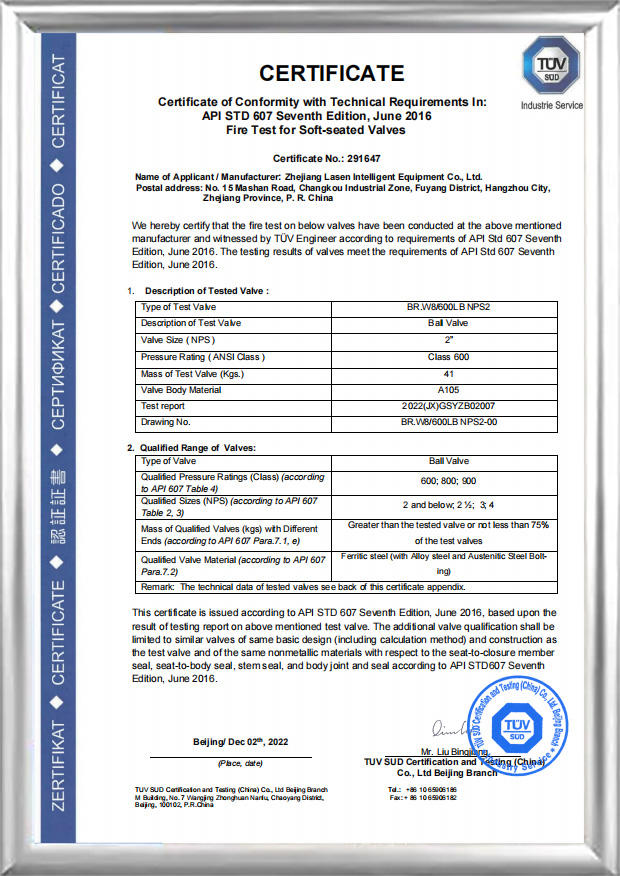

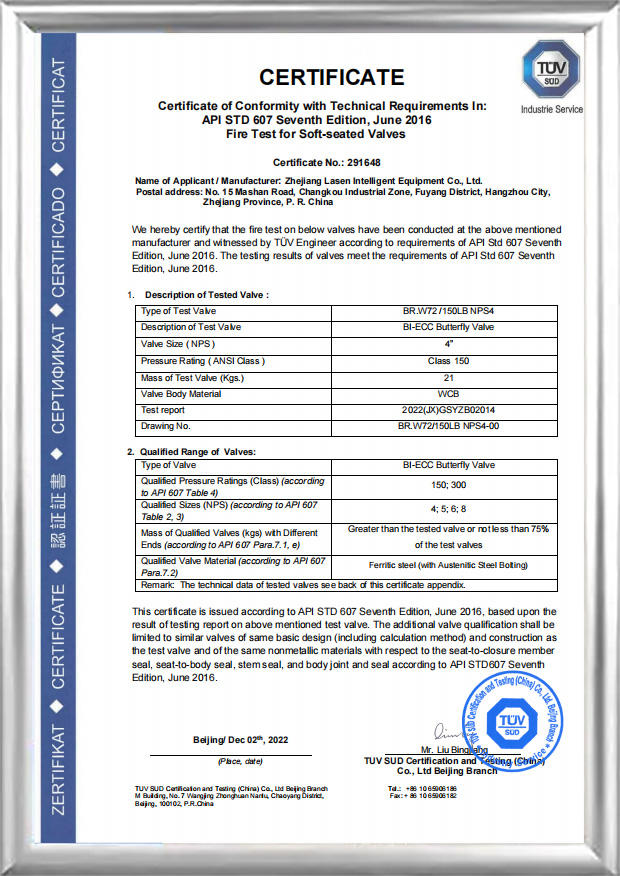

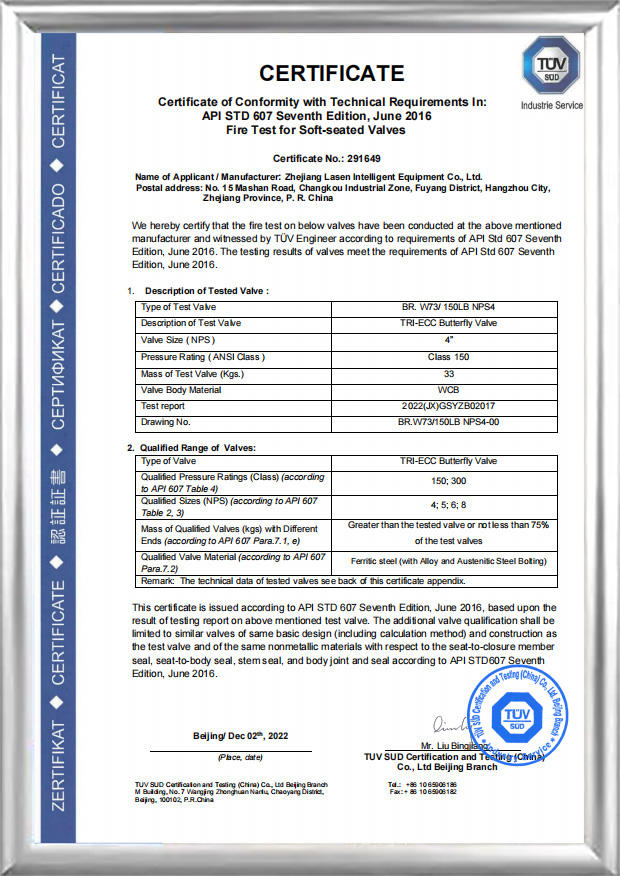

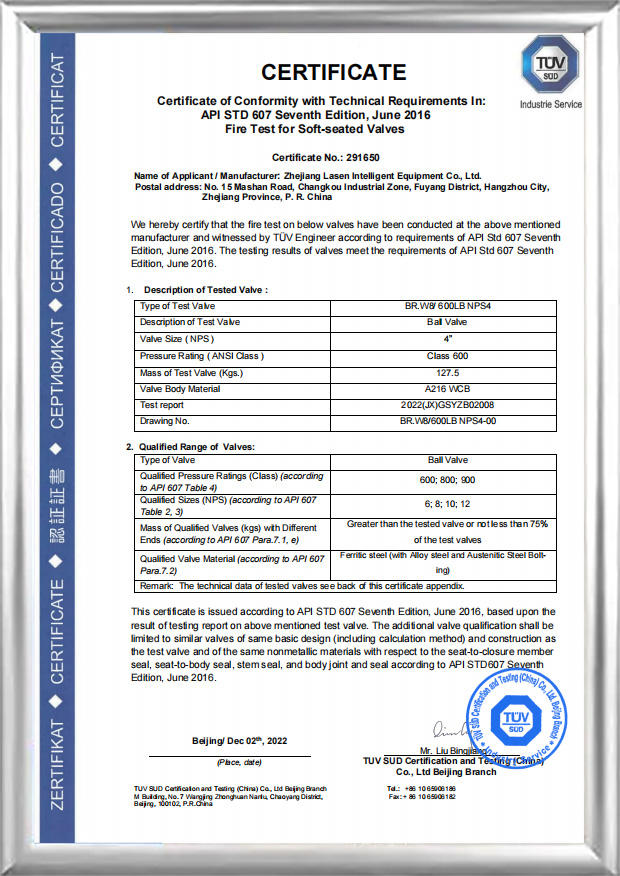

Our company is a national high-tech enterprise, a national science and technology-based small and medium-sized enterprise, an industry-university research teaching base of Zhejiang University of Technology, and a teaching base of "engineer training plan". We have passed ISO9001 \ ISO45001 management system certification, special equipment manufacturing license (class A1 certification) issued by the State Administration of market supervision, functional safety certification (safety integrity level reaches SIL2 / SIL3) and EU safety certification "CE", ball valve and butterfly valve products have passed API607 fire protection certification, regulating valve has passed ISO15848 valve low leakage rate certification, In the process of product development, our company continues to introduce international advanced technology and adopts CAD, CAE, CAM, FEA, and finite element analysis and design. At the same time, we have set up a new product R & D center, life test center, high-temperature test center and low-temperature test center, so as to ensure the quality of all our products. We also have a professional team engaged in R&D, manufacturing and management, marketing and finished product inspection of regulating valves for many years.

简体中文

简体中文 English

English русский

русский Español

Español Français

Français