Purpose and features:

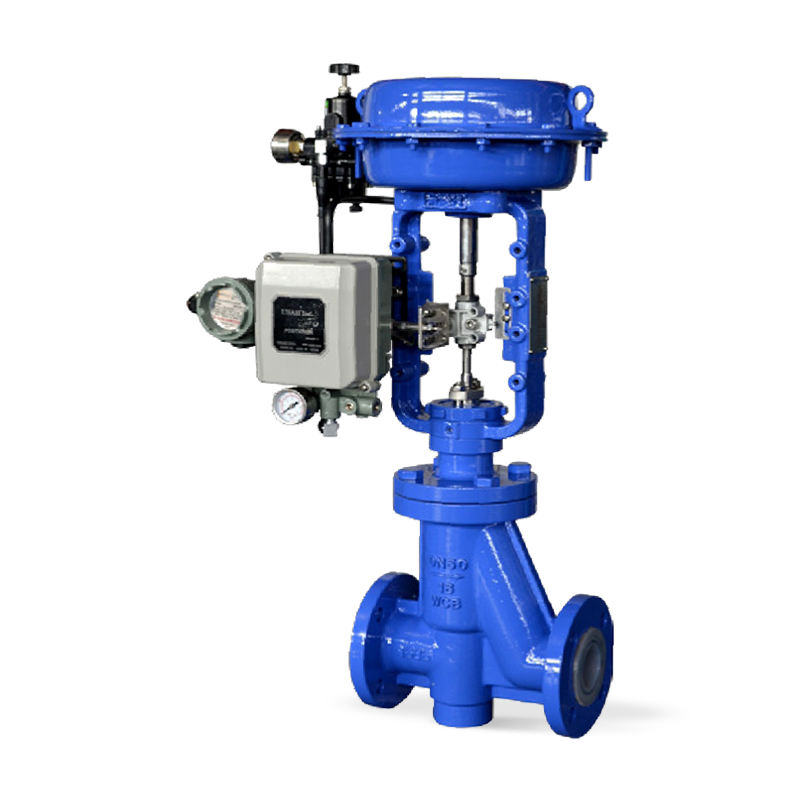

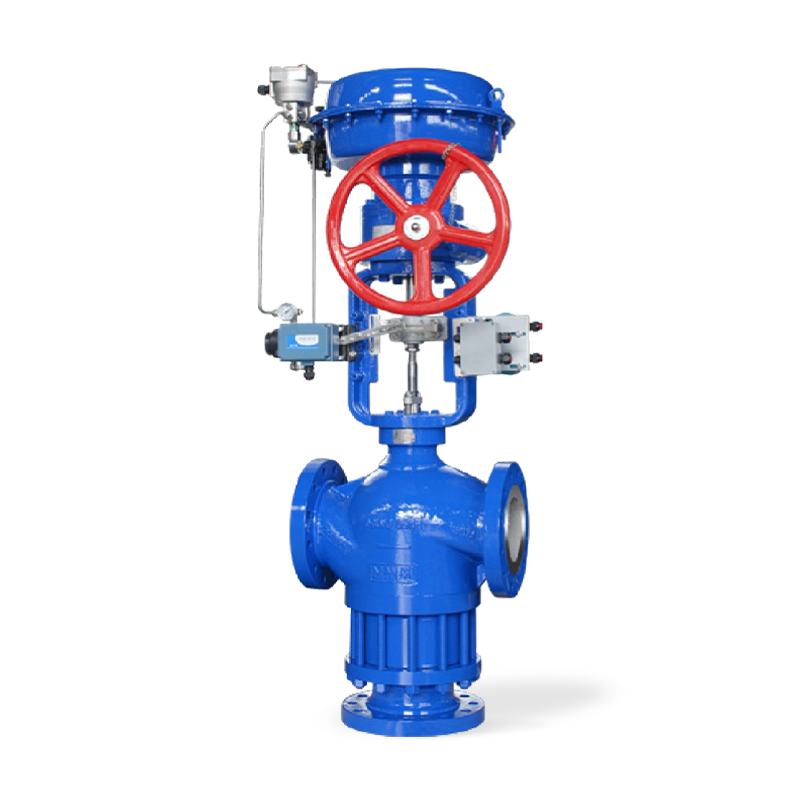

There are two types of throttling windows for the BR.W64 series sleeve regulating valves: the open window series and the multi-stage pressure drop series. The latter is designed to reduce the noise of compressible fluids, reduce flash, and prevent cavitation. To adapt to gas throttling diffusion and expansion, the sleeve is equipped with many symmetrical small holes to increase medium resistance, suitable for situations where high-pressure difference generates flash cavitation; Due to the fluid pressure balanced structure of the plug, stable adjustment can be achieved with only a small operating force.

This series of regulating valves can be equipped with spring pneumatic diaphragm actuators, pneumatic piston actuators, fully electronic intelligent electric actuators, etc. according to customer requirements.

This series of regulating valves can easily be made into special structures such as bellows sealing type, steam jacket type, and extended bonnet.

简体中文

简体中文 English

English русский

русский Español

Español Français

Français